When it comes to construction safety, you might underestimate the importance, or, you might have people on your crews who don’t take it seriously enough. It’s your responsibility to maintain a safe workplace and this post explains how and why it’s critical.

How Safe Is Your Construction Project?

From protecting your workers to avoiding hefty fines and penalties, the importance of construction safety cannot be overstated. However, if you’re not cultivating a culture of safety, your crews could be undermining your safety policies, without you being aware of it.

There’s much more to safety than having the best PPE. It requires everyone - from bookkeepers to subcontractors - to understand and follow your safety policies and procedures.

If you or your workers are not taking construction safety seriously, it might help to know construction is the leading contributor to workplace fatalities and injuries, according to research by the Ministry of Manpower’s 2021 Workplace Safety and Health Report.

Plus, the Work Injury Compensation Act (WICA) changed the way employees can report construction injuries. Now, rather than file civil charges, workers who experience job-related injuries need only claim it under WICA and don’t need an attorney to do so.

And they have a year to decide if they want to do it.

Nobody wants to see their workers hurt or injured. It’s not only poor leadership to not protect workers, but you risk much more by not providing proper construction safety training and developing a solid foundation for jobsite safety and enforcing a safety culture on the worksite.

What Is Construction Safety?

The Occupational Safety and Health Administration (OSHA) was formed in the 1960s, because “...more than 400,000 Americans were killed by work-related accidents and disease, and close to 50 million more suffered disabling injuries on the job," and these injuries had “cost billions of dollars in lost wages and production,” according to records.

You need only look at photos of some of history’s construction projects to see work conditions that would result in unknown amounts of injuries, losses, and fines today.

OSHA develops safety standards to protect workers, which are more stringent in tough, dangerous industries such as construction. From regulating how dangerous chemicals are handled and discarded, to the types of PPE and scaffolding used, every element of your jobsite has to follow these safety regulations.

Why Is Construction Safety Important?

If your worksites are not safe, neither are your workers, and neither is your company. Construction has a notoriously high level of difficulty finding skilled workers, and it’s crucial to protect the ones you have.

Having safety regulations also protects the public, since many construction projects are in populated areas.

But physical safety is not the only reason it’s important on your worksites.

You need a high level of safety standards for jobs that require bonding. And you’re much more likely to get such contracts if you have a positive and credible reputation in the industry.

Plus, you’ll save money. Your Experience Modification Rate (EMR) establishes the costs of your annual construction insurance. Insurance companies use your EMR to determine how much risk your company is.

OSHA reports the industry average EMR is 1.0 and if your experience is 20% better than average, it would be a .80; 20% worse would put you at 1.2 Your EMR is a way of rewarding safety-minded employers and penalizing those who don’t follow and enforce strong safety protocols.

The Bureau of Labor Statistics offers an online calculator to compute your company’s EMR and compare them to industry standards, based on your location and the number of incidents, accidents, and time claims you have.

Regardless, an unsafe worksite impacts your fiscal spending.

You’ll also find it difficult to fill labor positions if your firm has a reputation as an unsafe employer. It’s already a challenge to find skilled labor in construction, but being renowned as a company that doesn’t value worker safety, will compound the problem.

Today’s workers respect companies that prioritize their well-being and will be quick to jump ship if they join your crews only to discover you’re not providing a safe workplace for them.

Your workers are not the only ones who notice if you don’t have a safety-conscious culture. Your customers and clients, notice, too. Your reputation is a critical part of continued projects and word of mouth is one way new projects happen. You’re more likely to get positive references from your existing customers if they recognize your firm’s dedication to worker safety.

It's not just about focusing on regular construction safety topics meetings. It’s a type of workplace culture that has to be cultivated, nurtured, and enforced. Proper construction safety training not only keeps your workers, visitors, and the public safe but keeps you and your leaders out of trouble.

The Impacts of Poor Construction Project Safety

Poor construction safety frequently has devastating impacts. OSHA estimates employers pay almost $1 billion per week for direct workers’ compensation costs, plus indirect costs.

Accidents Eat Profits

All employees should be able to go to work without fear of injury or death and in the construction industry, it falls to the leaders to ensure safe worksites and create a culture of safety among your workers.

A workplace accident or injury increases your insurance premiums and you lose valuable time when a skilled worker becomes unable to perform. You’ll either spend time and money finding a replacement or have to put off the project until your worker is able to return.

Productivity Impacts

If you have to wait for a skilled worker to return to work (or find a replacement), your productivity declines significantly.

You’ll also find your employees’ morale will change after a workplace injury of one of their colleagues, and your reputation as a professional will make you less attractive to job-seekers.

Wages and Delays

Often the injured person’s wages must be paid by the company while they are booked-off work recuperating. This is a cost to the project overall.

Sometimes completed work, materials, tools, or other equipment is damaged in the accident. Repairing or replacing the items costs money and often causes delays. Delays result in additional costs and could result in the client imposing monetary penalties on the contractor.

Investigations

OSHA suggests all incidents be investigated, whether it’s a fatality, injury, illness, or close call but serious repercussions can happen if there is a serious incident, which the authorities will investigate.

These investigations tie up your worksite and could lead to hefty fines and possible imprisonment if a construction project manager, superintendent, supervisor, or foreman is found to be negligent.

If your firm becomes known for incident investigations, your employee morale will suffer, and your reputation as an employer will rapidly decline.

Safety Breaches

Poor safety frequently results in the project being shut down by the authorities until the safety breaches are rectified, which costs money and causes delays. It often also results in negative publicity which impacts your company’s reputation as a contractor and an employer. You may also be held financially responsible and be ordered to pay hefty fines for safety violations.

Records

It’s challenging to find skilled workers, and having a record as an unsafe employer hurts your chances of building a strong team and company. When you have numerous safety incidents on your record, not only do craftsmen hear about it, but your potential clients do, too.

Health

If you’re not employing proper construction safety training, you put yourself at risk, too. It’s not just your job to protect workers, but having consistently safe worksites helps keep you safe as well.

If you have multiple jobsites, imagine going to check progress, only to be a victim of an incident due to poor safety conditions that you didn’t know were there, because you have not built a strong safety culture in your teams.

What’s the Problem?

It seems it would be obvious that construction leaders would prioritize safety on the job, but this is sadly not the case. The construction industry is a dangerous one, and workers don’t want to work for a company that puts their lives at risk.

Sadly, 51% of construction workers surveyed by the National Safety Council said they believe management does the bare minimum for the sake of the law, to protect their safety, and only 36% feel their safety is a priority.

That’s why you have to instill an urgent sense of safety in everyone who works for you - from bookkeeper to errand runner to C-Suite.

The American Society of Safety Professionals suggests implementing a safety and health management system, to establish and enforce the safest possible worksites.

They assert there are a minimum of five things your safety and health management system should address.

1. Education

Safety training is not just about avoiding the fatal four. It’s also about understanding the very real risks associated with construction and learning to take them very seriously. Your crews should also be taught how different conditions can change existing hazards and/or create new ones, such as an unexpected downpour in the day, or unscheduled deliveries that could cause disruption.

Hold frequent tool talks of 10 to 15 minutes to reinforce the importance of safety and further educate your crews.

2. Be mindful of Employee Well-being

Safety in construction is more than just on the job. Exhausted, distressed workers increase the likelihood of careless mistakes and safety violations. According to research, the construction industry is rife with addictions and disorders:

- 12% have an alcohol use disorder compared to 7.5% nationally

- 16.5% of construction workers reported heavy alcohol consumption within the past month, nearly twice the average of all full-time workers surveyed

- 11.6% of construction workers reported illicit drug use within the past month

- 14.3% of construction workers were diagnosed with a substance use disorder in the past year, more than 1 ½ times the average of all full-time workers surveyed

- 2.3% have a marijuana use disorder

When your employees feel safe and cared for, they’re less likely to develop these issues. Foster a climate of understanding and consider employee assistance programs or offer a no-questions-asked support system, so they feel comfortable asking for help when they’re going through a tough spot.

3. Understand Projects

In construction, there are often multiple different teams working, from different employers. Every member of every team should be clear on the scope of the project, what they’re supposed to do, the safety requirements, and who’s responsible for what.

There may be different safety requirements for different types of workers, and everyone needs to understand safety compliance.

Make sure your contractors, project managers, and safety professionals remain aware of any special regulatory requirements and commit to monitoring and enforcing them.

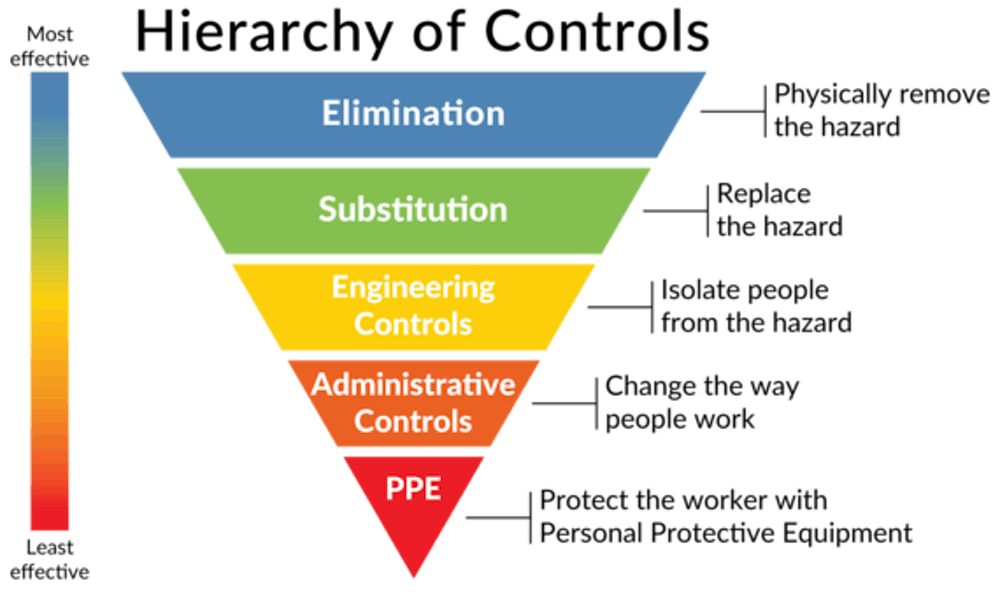

4. Understand and teach the Hierarchy of Controls

The Hierarchy of Controls has existed for decades and has been proven effective in many industries. Rather than having everyone on the job site doing everything with PPE, examine ways you can educate your workers on the Hierarchy of Controls, so they have a clear understanding of alternative ways to handle workplace hazards.

Removing the hazards or substituting is a more effective means than using a pair of safety goggles, for example. So make sure you, your foreman, and your leaders are all educated in the Hierarchy of Controls. With this model deeply ingrained, it will help foster a safety-conscious workforce.

5. Employ Effective Safety Management

You can’t be everywhere all at once to monitor safety issues but you can incorporate others to be as rigorous about safety as you are. OSHA’s Recommended Practices for Safety and Health Programs outlines seven steps to establishing a thorough safety management program.

- Management leadership

- Worker participation

- Hazard identification and assessment

- Hazard prevention and control

- Program evaluation and improvement

- Communication and Coordination for Host Employers, Contractors, and Staffing Agencies

Communication is at the core of an effective safety management program, and for building a solid safety culture among your workers. Safety-conscious leadership is also necessary to reinforce the importance of proper safety protocols and procedures.

Construction Safety Is Everyone’s Job

Safety is an annoyance that must be adhered to for the sake of staying compliant. But it’s much more than that.

Without regulations, more workers would be injured - or worse - on the job. Particularly in high-risk industries like construction. But your company should not follow safety regulations because you’re required to. Rather, safety should be part of the foundation of your workers’ ethics.

To accomplish this, you must incorporate solid safety training and continuously emphasize the importance of construction safety. Ensure your leaders share a commitment to safety so you, your workers, and your company are at less risk of safety problems.

ClockShark’s Clock Out Questions help keep your workers and worksites safer. You can customize questions to be text, multiple choice, or yes/no, and require questions to be answered before your workers clock out. Plus, being able to run reports based on the responses received, you’re able to ascertain patterns or problems that may not have been otherwise identified. Sign up for a free trial now.