When it comes to job costing, most small construction companies fit into one of three categories. They don’t job cost at all. They job cost, but they measure too few items to be effective. Or they go too far and measure too much.

Very few go the Goldilocks route and get job costing just right, says Gregg Schoppman, principal at the construction management and consulting firm FMI.

“The ones that don't capture anything at all have no predictability,” says Schoppman. “They don't really know how their jobs are doing until the final nail is in the building -- or the coffin, as I like to say in their case.

“The other group is what I call codes in infancy, or job costing in infancy. For instance, if they’re a plumbing contractor, and they're measuring two things like above ground and below ground. At least they're measuring something, but it's like taking a teaspoon out of an ocean.

“Then there are the companies that swing the pendulum so far to the right that they measure everything. And unfortunately, it becomes tedious, cumbersome,” says Schoppman.

When job costing is tedious, people in the field get overwhelmed and add their time or expenses in whatever bucket suits them, whether it’s the right one or not. Then you can’t trust the numbers to tell you the truth about what’s happening in your business.

And that defeats the purpose of job costing.

What is the purpose of job costing and how should you use it?

Job costing is about more than having a bucket for income and a bucket for expenses. You start with those things, yes. But you also need to allocate them to specific parts of each job, along with other units of measure, like percentages of jobs completed.

If you skip this step, then you can’t use job costing to understand productivity or profitability. And you won’t be able to use the data to guide your business decisions.

And that’s what the heart of job costing is all about -- making decisions that improve productivity, increase your bottom line, and help you grow.

“Job costing allows you to better track where your costs are going, so that you can learn more about your business,” says Dawn Killough, construction writer and 25 year veteran of construction accounting.

“You're attributing your revenue and your costs to projects, then using that information to determine how profitable a project was or to get information about your productivity.

“[Job costing] can inform anything from how you bid projects, to making decisions about hiring or expansion. It’s a learning tool,” says Killough.

And Schoppman agrees.

“There's got to be this weave between job costing, cash flow management, billing, and more importantly, how the job is going.”

For example, have you ever underestimated how much a job would cost and lost money?

If you were job costing on that project, you could look back at that data and see where you lost the money. DId it take more materials than you estimated? More labor hours? Did you forget to figure in the cost of overhead or equipment rentals?

When you do job costing right, you can see where you’re bleeding. Then the next time you bid a job, you’ll know where to charge more, so you don’t lose money or just break even.

But job costing correctly, so that it can serve its intended purpose, can be difficult.

“There's a sizable disconnect in all firms, small, large, and medium,” says Schoppman. “They bid one way, and they charge their time in another. The two shall never meet and have that good dialogue at the end to say, ‘What did we do well? What did we do poorly?’”

There are several common roadblocks that cause these disconnects. If you know what they are, you can overcome them and finally reap the rewards that good job costing brings.

Common roadblocks to job costing and how to overcome them

The first, and biggest, roadblock for small to mid sized construction firms is this:

1. Not Knowing Where or How to Get Started

Starting anything new can feel overwhelming, especially when it involves as many moving pieces as job costing.

The key is to start small and learn the basics.

You already know the purpose of job costing. So use that as a guiding light to structure the best system for your company.

And remember that no two construction companies are exactly the same. General contractors will obviously need to keep track of more than a concrete contractor. The idea is to create a coding system that works for your particular needs.

The best place to start is by outlining your direct and indirect costs. Then determine the codes that correlate to those costs. You can make up your own coding system, or you can use CSI’s list of standardized construction cost codes.

It may take some trial and error to get the perfect number of codes. (There will be more on that a little further down.) But once you know which codes to use, you can start using them to gather data immediately.

Just be careful not to dive in too hard, too fast.

“Don't all of a sudden try to go back and categorize everything and get caught up in a big project,” says Killough. “Start from the next project you get. Then slowly make sure you're doing your job costing as you go.

“Your reporting will be crazy for a little while, because you'll have some things that you won't have information on.” But that’s perfectly normal when you first start job costing.

The problem comes when you’ve been job costing for a while and your reporting is still off.

If that happens, you’re probably bumping into one of these other roadblocks:

2. Not Using the Right Number of Codes

Use too few codes and you won’t see a big enough picture of your job costs to understand what they’re telling you. It’s the teaspoon in the ocean scenario.

“A good example of this is in stormwater systems for a civil contractor,” says Schoppman. “When you're estimating a project like that, you'll have like 30 manholes, different types of reinforced concrete pipe, and different depths.”

So to label all the pipes with the same cost code would be too much in one code. It would be better to use a code that specifies the piping but also includes where it’s being used: on the north, south, east or west quadrant of the property.

“It's the same code but we Have it divided by territories,” says Schoppman. “So as I'm statusing my progress, it's not the teaspoon out of the ocean. It's a teaspoon out of a manageable puddle.”

On the flip side, if you get too granular and use too many codes, your costs will be misappropriated.

So, how can you find the right balance between too few and too many codes?

“There's a Pareto principle, or 80/20 rule, when it comes to finding the right number of codes,” says Schoppman. “When you look at how the hours are distributed, usually about 80 percent of the hours are in about 20 percent of the work items.

“So, run a couple of reports, look at where you think the work is, and you'll find there's really only a handful of items.”

Keeping the number of cost codes manageable doesn’t only give you a better picture of where your costs are going. It also helps make job costing field friendly, which is another place companies often miss the mark.

3. Not Making Job Costing Field Friendly

“If I go out and buy a bunch of plywood, that’s fairly easy to track,” says Schoppman. “The real wild card is labor cost feedback.”

That’s why it’s so important to make sure your job costing system is field friendly.

“Too many companies make it where estimators get what they want and the accountants get what they want. But unfortunately, without the right setup and involvement of the field, you're simply going to get G.I.G.O. [garbage in, garbage out],” says Schoppman. “There's no real integrity in the data.”

Killough confirms that inaccurate information from field crews is a common problem.

“How the field thinks something should be coded doesn't necessarily match what the office might think,” she says.

To combat this, Schoppman suggests including your field teams in the pre planning stages of a project.

“Good pre-construction planning is collaborative,” says Schopman.

You can’t just hand your superintendent a binder with 250 cost codes, give no explanation, and say, “See you in six months.” You have to go over the codes, and make sure your crews know what they mean and how to use them.

Plus you need some kind of job cost tracking that makes data entry easy for the field.

Ask yourself, “Does the field have a tool that's workable for them?” If the answer is “no,” then you’ve run into the next roadblock that hinders job costing success.

4. Using the Wrong Software

Having your field team keep up with paper time cards and receipts, so the office can manually enter them into an Excel spreadsheet is better than doing nothing. But only slightly.

“That’s a lot of work,” says Killough.

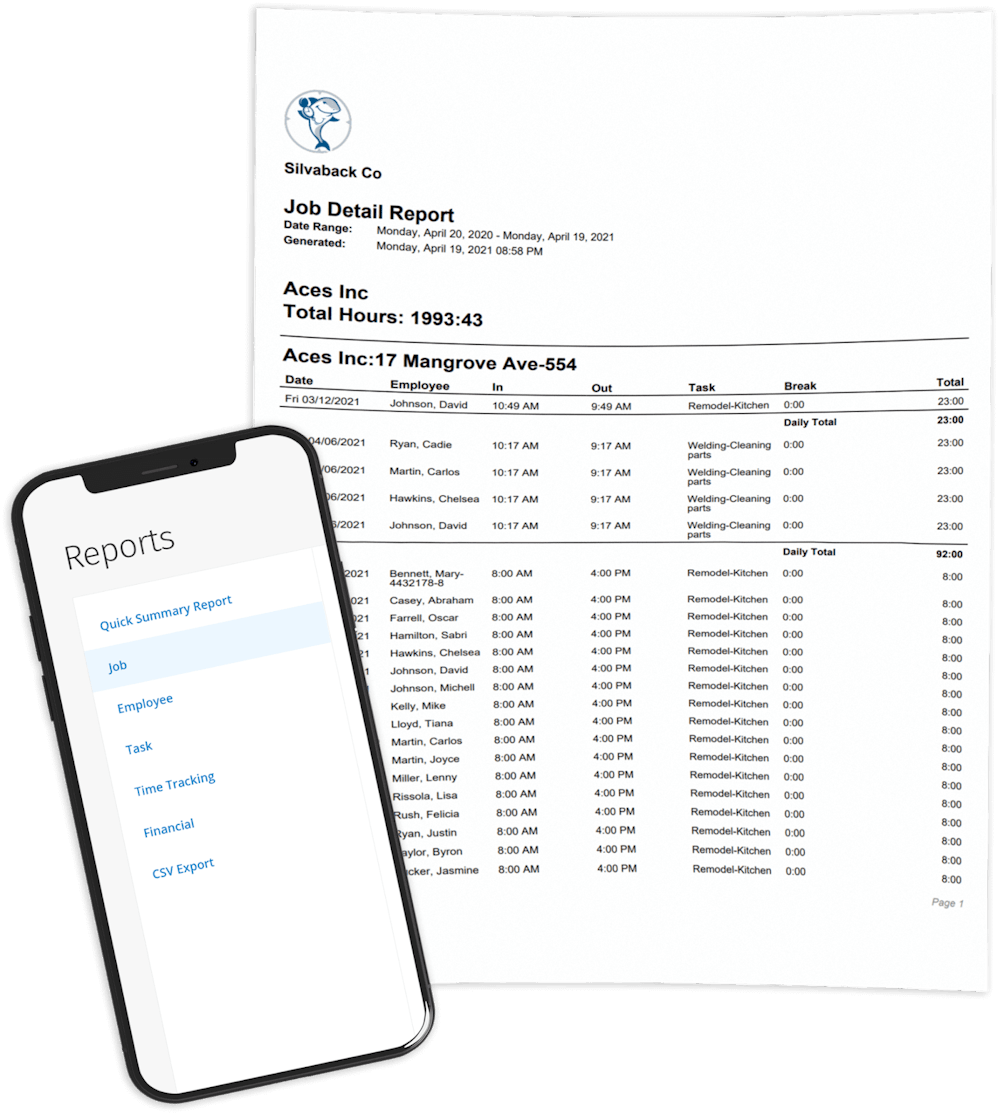

She explains that even though you can tag each expense to a job in Excel, it’s very difficult to run reports. Using accounting software, on the other hand, makes reporting simple.

“You click one button to get a report and poof, the information is there,” says Killough. “You don't have to add it up. You just hit a button and the software's categorizing it for you.”

And you don’t have to rely on generic accounting software like Quicken or Freshbooks, either. There are many construction job costing software options.

“Some of the systems that I've seen recently allow for a lot more input from the field,” says Killough. “They're taking pictures, uploading it, and they're able to code it.”

Once your field crews have a manageable number of codes and an easy way to keep track of them in the field, your job costing will become much more accurate.

When your numbers are accurate, you can start using them to better steer your business. But you can’t use job costing to course correct if you aren’t measuring progress as well as time.

5. Not Measuring Job Progression

Productivity directly impacts profitability. So you have to track progress percentages and/or know how many units are installed along with the number of hours worked.

“Hours by themselves don't tell me much,” says Schoppman. “My superintendent put a charge for 48 hours for his crew today. But did he show how much he completed? You need both to really see performance.”

And, if the labor and the performance aren’t equaling out like they should, you need to figure out the problem.

“If they charged 48 hours today and they only got one unit in place, I should be on the phone with my field leader saying, ‘What happened?’” says Schoppman.

Measuring progress along with time allows you to see when and where course corrections should be made, so you can keep your jobs on track.

6. Overlooking or Ignoring Burden and Indirect Costs

If your job costing reports show that you’re making a profit, but your financial statements don’t agree, it’s likely because you haven’t included burden costs, like insurance and taxes. Or maybe you haven’t assigned a place for your indirect costs like owned inventory or fuel.

You have to have a system that takes these things into account.

Take a civil contractor who owns their own equipment as an example. If they’re out performing jobs, they’re adding wear and tear to those vehicles. They're using fuel. They’re having to do preventative maintenance. Those costs add up.

But if they forget to charge these costs to jobs, then they’re getting a very skewed view of their actual profits. And they could be losing money without knowing why.

“It's the little things that end up biting us,” says Schoppman.

Conclusion

Sometimes the right steps to take in your business seem counterintuitive at first. Why take away time and energy from doing the actual work to gather construction job costing data?

But the thing is, when done right, job costing will actually save you time and energy.

Here are just a few benefits that make job costing worth it:

- Job costing helps you get your bids right, so you can say goodbye to tiny profit margins.

- Job costing helps you grow with fewer pains. Once you hit that $2 Million mark, and you have to fill out WIP reports, you’ll already have the job costing info you need.

- Job costing helps you make course corrections when productivity is off. So you can complete projects on time.

“From an ease of use standpoint, a contractor may not want to do it,” says Killough. “But from business management, and learning, and trying to grow your company, there's so much information you can get from job costing that it doesn't make sense not to do it.”