Despite construction workers making up only 6% of the national workforce, they account for nearly 40% of all occupational heat-related deaths. That's a staggering statistic. It becomes even more alarming when you consider this: the next five summers are expected to be the hottest on record. As temperatures rise, so does the likelihood of construction heat-related illnesses (HRIs).

The Impact of Heat on Construction Workers

Construction workers spend summers exerting themselves in the heat and humidity. This combination of heat, humidity, and exercise creates heat gain in their bodies which is often compounded by the personal protective equipment (PPE) they have to wear.

As their heat gain rises, their capacity to work at full throttle lowers. For example, when it’s 86°F with 45 percent humidity, mental and physical functionality drops to 85 percent. At 95°F with 75 percent humidity, their ability to work drops to 50 percent.

Workers who try to power through the heat actually lose productivity. They are also at greater risk for dehydration and these other HRIs:

Heat Syncope

Small blood vessels dilate in hot temperatures, slowing the body's heating process. As the vessels expand, blood pressure drops and reduces blood flow to the brain. This results in light-headedness, dizziness, and fainting, known as heat syncope. Dehydration and lack of acclimation to the heat contribute to the condition.

Workers who experience heat syncope should sit or lie down in a cool area, elevate their legs, and rehydrate. While heat syncope can be one of the lesser construction summer challenges, it can also be a symptom of a more severe condition like heat stroke. (See below.)

Heat Cramps

Heat cramps are painful muscle spasms caused by salt and fluid loss from excessive sweating. They often affect muscles in the abdomen, shoulders, arms, and legs.

Workers experiencing heat cramps should take a break, cool down, and drink fluids with electrolytes. Seek medical help if the person affected is on a low-sodium diet, suffers from heart issues, or if the cramps don't subside within an hour. Heat cramps can resolve on their own or be a sign of a more serious condition. (See below.)

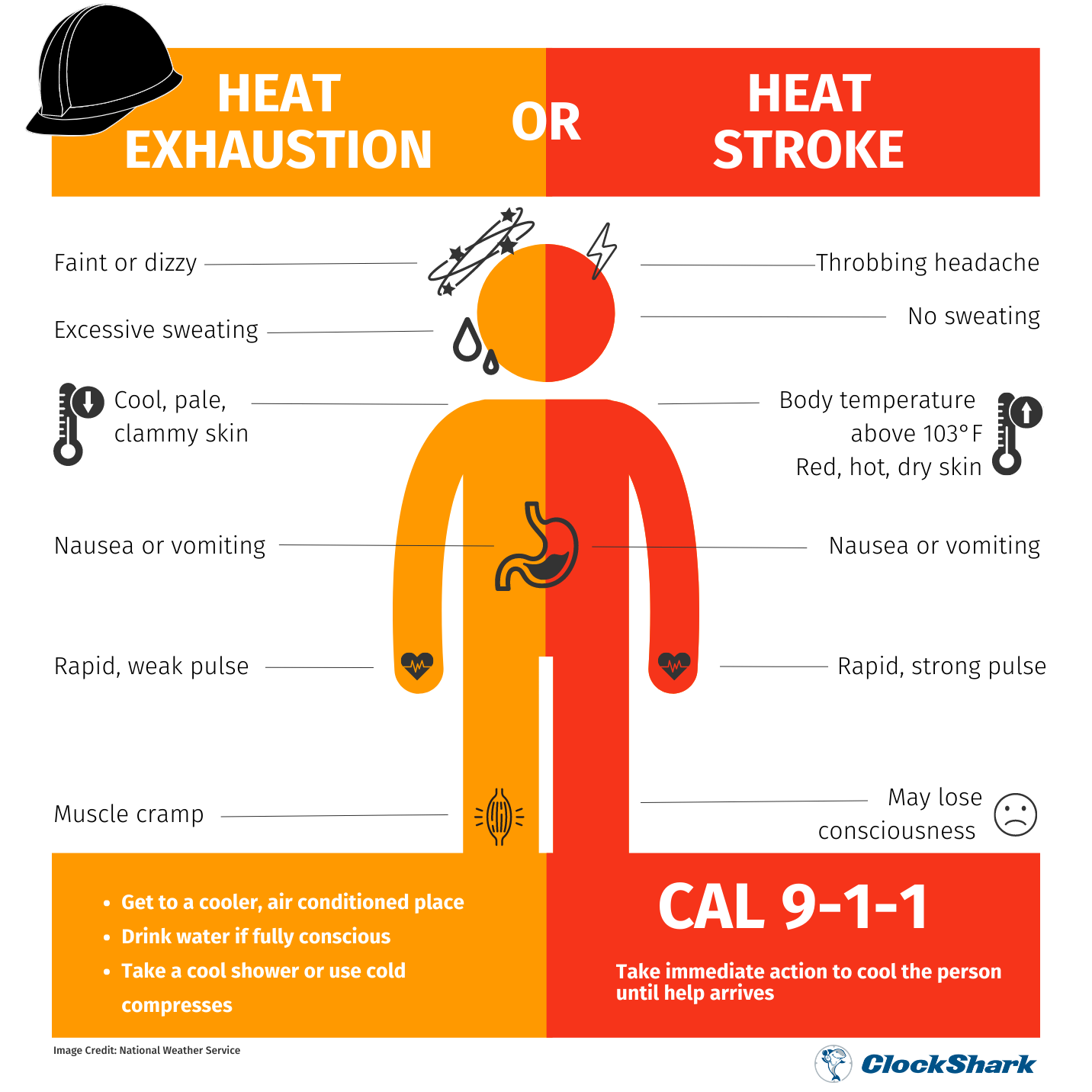

Heat Exhaustion

Heat exhaustion results from too much fluid loss, too much salt loss, or both. The body becomes dehydrated, overheats, and reaches a temperature of 101°F or greater. Thirst, headache, decreased urination, dizziness, and heat cramps are all signs of heat exhaustion.

Workers showing signs of heat exhaustion should be removed from the heat and given immediate medical attention. Call 911 if medical care isn't available. Take these cooling measures as soon as possible:

- Remove unnecessary clothing, including PPE, shoes, and socks.

- Provide cold compresses and wet the head, neck, and feet with cool water.

- Give small, frequent sips of water and sports drinks.

Never leave a worker with heat exhaustion alone. Heat exhaustion can rapidly transition to heat stroke.

Heat Stroke

Heat stroke is the most dangerous HRI for construction workers. When experiencing heat stroke, the body loses its ability to regulate its temperature. Within 10 minutes, it can soar as high as 106°F. Signs of heat stroke include confusion, slurred speech, fainting, and seizures. Heat stroke can cause brain damage, permanent disability, or death if left untreated.

If a worker is experiencing heat stroke, call 911 immediately, and take these measures as you wait for help:

- Move the worker to an air-conditioned or shaded location if possible.

- Wet skin and clothes with cool water.

- Use ice packs or cold compresses on the neck and head.

- Stay with them until help arrives.

While working in the heat increases the risks of these summer construction challenges, HRIs are preventable.

How to Help Workers Stay Cool While Working in the Heat

Take these steps to keep crews safe when temperatures soar:

1. Ease Workers Into the Heat

Gradually increase the time workers spend in the heat. This gives their bodies time to acclimate to working in hot temperatures. Acclimation periods take an average of two weeks, depending on individual factors like age, underlying medical conditions, and overall health.

OSHA recommends that new workers, or those who have been absent for an extended period of time, start with 20 percent of their workload on the first day of work. Increase workloads by no more than 20 percent per day until workers are fully adjusted. Even experienced workers should reduce their workload to 50 percent during sudden heat waves.

2. Start the Day Early

When possible, schedule the most physically demanding work at the beginning of the day – when it’s cooler outside. Save the less labor-intensive tasks for hot parts of the day.

3. Schedule Frequent Breaks

Frequent breaks allow workers to cool down properly and stay hydrated. Calculate how many breaks your crews need by accounting for the heat index and exertion levels. For example, the National Institute for Occupational Safety and Health (NIOSH) recommends a 15-minute rest break every 45 minutes for workers performing moderate activity on 100°F days at 30 percent humidity.

4. Ensure Workers Stay Hydrated

Provide easy access to drinking water as well as access to drinks that contain electrolytes. Workers should not wait until they are thirsty to drink. Thirst is the first sign of dehydration. Drinking one liter of fluid per hour is a good rule of thumb. That’s one cup every 15 minutes.

5. Provide Shade

Use tents and canopies to provide a shady area for employees to rest. When possible, provide misting tents or fans.

6. Monitor Conditions with Teamwork and Tech

Use teamwork and tech to track environmental conditions and monitor employee heat-stress levels.

- Train crews to identify the signs of heat illness and use a buddy system to avoid risks.

- Download the OSHA-NIOSH Heat Safety Tool app to calculate the heat index and see the heat risk for the day.

- Invest in wearable health monitors to alert employees to overheating.

Conclusion

Summer heat can be a real killer for construction workers. Treating heat risks seriously and creating plans to mitigate their adverse effects will keep workers safe and improve productivity.

Creating processes and plans is a must to make your business run smoothly. If you’d like to learn how to create an effective quality control process and download a free quality control checklist, read our blog post, 10 Tips for Quality Control in Construction.